Fill a Valid Welder Performance Qualification Record Template

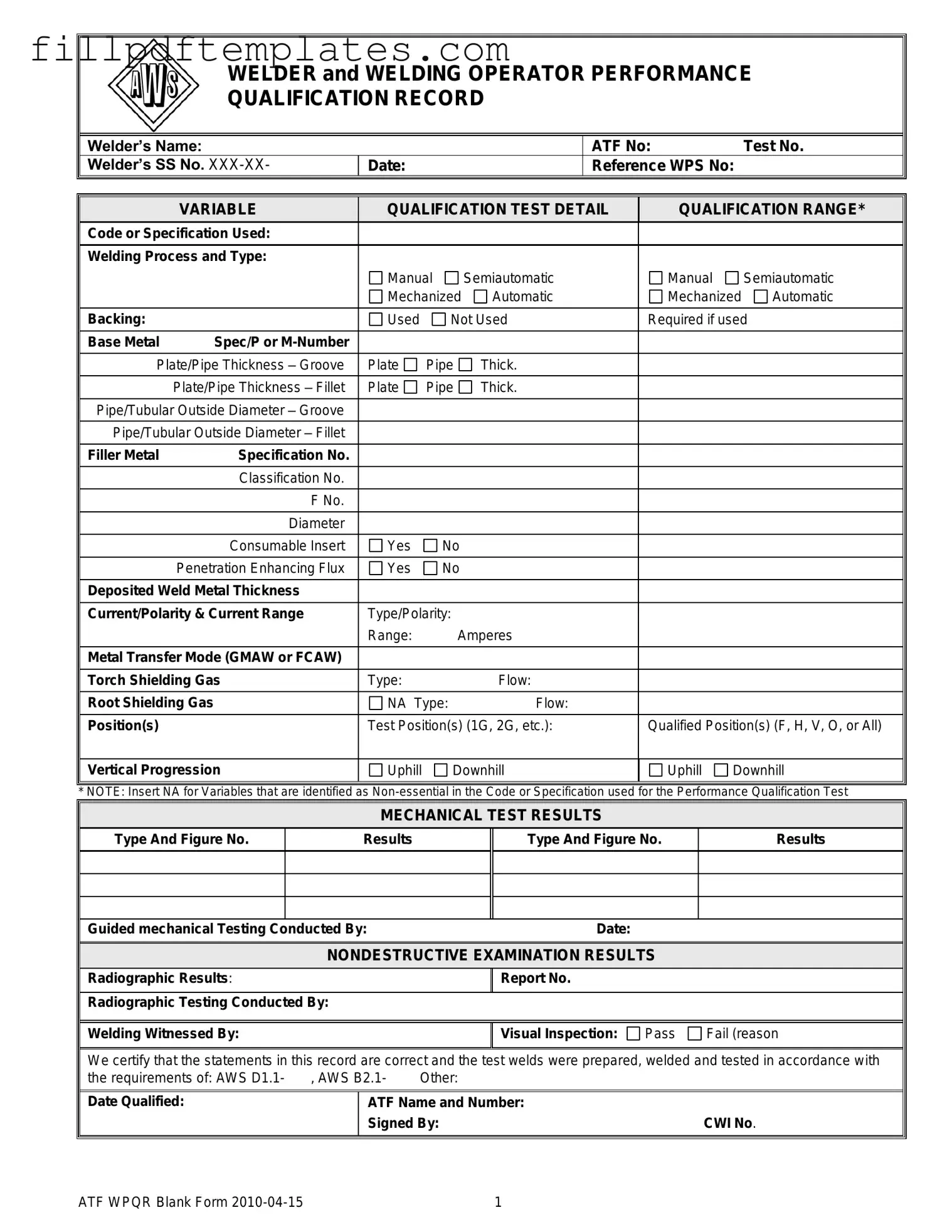

The Welder Performance Qualification Record (WPQR) form serves as a critical document in the welding industry, ensuring that welders meet the necessary standards for skill and safety. This form captures essential information about the welder, including their name, identification numbers, and the specific test they undertook. It details the reference Welding Procedure Specification (WPS) used during qualification, which outlines the parameters and techniques that the welder must follow. The WPQR also includes a comprehensive section on the variables involved in the qualification test, such as the type of welding process employed—manual, semiautomatic, or automatic—as well as details about the base metal and filler metal specifications. Additionally, it records the positions in which the welder is qualified to operate, ranging from flat to vertical, and notes the results of both mechanical tests and non-destructive examinations. The form concludes with a certification statement, confirming that all tests were conducted according to relevant codes, such as AWS D1.1 or AWS B2.1, thereby ensuring the integrity and reliability of the welding work performed. This document not only verifies a welder's capabilities but also plays a vital role in maintaining industry standards and safety protocols.

Additional PDF Templates

Rst Form Army - Responsible officers must ensure the form is submitted to the correct authority for processing.

Shared Well Agreement Template - The agreement is essential for securing reliable water resources for both homes.

Understanding the details presented in the pay stub is crucial for any employee, as it ensures transparency regarding their earnings and deductions. The information provided in the ADP Pay Stub form is invaluable, and for those seeking to delve deeper into the specifics of their pay statement, resources such as the ADP Pay Statement can offer additional clarity and guidance.

Employee Status Change Form Template - Support modifications in employee benefits eligibility.

Similar forms

- Welding Procedure Specification (WPS): Similar to the Welder Performance Qualification Record, the WPS outlines the procedures for welding, including the materials and methods to be used. It serves as a guideline for welders to ensure consistency and quality in their work.

- Procedure Qualification Record (PQR): This document verifies that a specific welding procedure can produce a weld meeting the required standards. It includes details about the tests performed and results, much like the performance qualifications recorded for welders.

- Welder Certification: This certificate confirms that a welder has successfully completed a qualification test. It is essential for validating a welder's skills, similar to how the Welder Performance Qualification Record demonstrates a welder's capabilities.

- Welding Inspection Report: This report provides a summary of the inspections conducted on welds. It shares similarities with the Welder Performance Qualification Record by documenting the quality and compliance of the welds produced.

- New York ATV Bill of Sale form: This essential document records the private sale of an All-Terrain Vehicle (ATV) and is critical for both buyer and seller. For your convenience, click here to download the form and ensure a smooth transfer of ownership.

- Non-Destructive Testing (NDT) Report: This report details the results of tests performed to assess the integrity of welds without damaging them. Like the qualification record, it is critical for ensuring the quality of welds.

- Welding Log: A welding log tracks the details of welding activities, including times, materials, and processes used. It parallels the Welder Performance Qualification Record by documenting essential information about welding performance.

- Quality Control Plan: This plan outlines the procedures and standards for maintaining quality in welding operations. It shares a focus on compliance and quality assurance, similar to the objectives of the Welder Performance Qualification Record.

Document Specifics

| Fact Name | Description |

|---|---|

| Purpose | The Welder Performance Qualification Record form verifies that a welder has the necessary skills to perform welding tasks according to specific standards. |

| Governing Standards | This form is often used in accordance with standards such as AWS D1.1 and AWS B2.1, which outline requirements for welding qualifications. |

| Required Information | Key details must be filled out, including the welder’s name, identification numbers, test results, and the specifications used during the qualification process. |

| Testing Methods | The form includes sections for both destructive and non-destructive testing results, ensuring comprehensive evaluation of the welds. |

| Qualification Range | Welders are qualified for specific processes and positions, such as manual or automatic welding, and various joint configurations. |

| Certification | Upon completion, the form must be signed by a Certified Welding Inspector (CWI), confirming that the welding meets all required standards. |

Things You Should Know About This Form

-

What is the purpose of the Welder Performance Qualification Record (WPQR)?

The WPQR serves to document a welder's qualifications and the specific tests they have passed. It verifies that the welder is capable of performing welds according to industry standards and specifications. This record is essential for employers and regulatory bodies to ensure that welders meet the necessary skill levels for various welding processes.

-

Who needs to fill out the WPQR?

The WPQR must be completed by the welder or welding operator undergoing qualification testing. Additionally, a Certified Welding Inspector (CWI) or another qualified individual must verify the results and sign the document to confirm its accuracy.

-

What information is required on the WPQR?

The WPQR requires several key pieces of information, including:

- Welder's name and identification numbers

- Test number and date

- Welding Procedure Specification (WPS) number

- Details about the welding process, base metal, filler metal, and test results

- Non-destructive examination results

-

What types of tests are documented on the WPQR?

The WPQR documents various tests, including mechanical tests that assess the strength and durability of the welds. It also includes results from non-destructive examinations, such as radiographic testing and visual inspections, to ensure the quality of the welds.

-

How long is the WPQR valid?

The validity of a WPQR can depend on the specific requirements of the industry and the governing codes. Generally, as long as the welder continues to work in the same processes and does not have a significant break in welding activity, the qualification remains valid. However, periodic requalification may be necessary based on company policies or regulatory requirements.

-

What happens if a welder fails a test?

If a welder fails a test, the WPQR will reflect this outcome. The welder may need to undergo additional training or practice before retaking the test. It's crucial for the welder to understand the reasons for the failure to improve their skills and increase their chances of passing in subsequent attempts.

-

Can a WPQR be transferred between employers?

A WPQR is generally specific to the welder's qualifications under a particular employer and their procedures. However, it can be used as a reference when seeking employment with another company. The new employer may require additional tests or verification to ensure that the welder meets their specific standards.

-

What is the significance of the signatures on the WPQR?

The signatures on the WPQR indicate that the information provided is accurate and that the tests were conducted according to the required standards. The welder's signature confirms their agreement with the record, while the CWI's signature ensures that the testing process and results are valid and reliable.

-

Where should the WPQR be stored?

The WPQR should be stored in a secure location, typically within the company's records management system. It is important for both the welder and the employer to have access to this document for future reference, audits, or inspections. Proper storage helps maintain compliance with industry regulations.

Documents used along the form

When qualifying a welder, several documents complement the Welder Performance Qualification Record (WPQR) form. Each of these documents plays a crucial role in ensuring that the welder meets the necessary standards and requirements. Below is a list of these forms and documents, along with a brief description of their purpose.

- Welding Procedure Specification (WPS): This document outlines the specific procedures and parameters for welding. It includes details such as the type of materials, welding techniques, and equipment to be used. The WPS ensures consistency and quality in welding practices.

- Last Will and Testament Form: To safeguard your estate planning, refer to the important Last Will and Testament resources that outline essential procedures for documenting your final wishes.

- Procedure Qualification Record (PQR): The PQR is a record that demonstrates that the welding procedure outlined in the WPS can produce welds that meet the required standards. It includes results from mechanical tests and other evaluations performed on the welds.

- Material Test Reports (MTR): MTRs provide certification of the materials used in the welding process. These reports confirm that the materials meet specific standards and specifications, ensuring quality and reliability in the final product.

- Non-Destructive Testing (NDT) Reports: NDT reports document the results of inspections performed on the welds without damaging them. Common methods include radiographic testing and ultrasonic testing, which help identify any defects or inconsistencies in the welds.

- Welder Certification: This document verifies that the welder has completed the necessary training and passed examinations to qualify for specific welding processes. It serves as proof of the welder's skills and knowledge.

- Visual Inspection Reports: These reports detail the findings from visual inspections of the welds. They indicate whether the welds pass or fail based on established criteria, providing an initial assessment of weld quality.

- Heat Treatment Records: If applicable, these records document any heat treatment processes applied to the welded materials. They ensure that the materials have been properly treated to enhance their mechanical properties and performance.

Each of these documents supports the overall qualification process for welders, ensuring that they are capable of producing high-quality welds that meet industry standards. Together, they create a comprehensive framework for evaluating and certifying welding performance.

Welder Performance Qualification Record Preview

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||